Reviews

Description

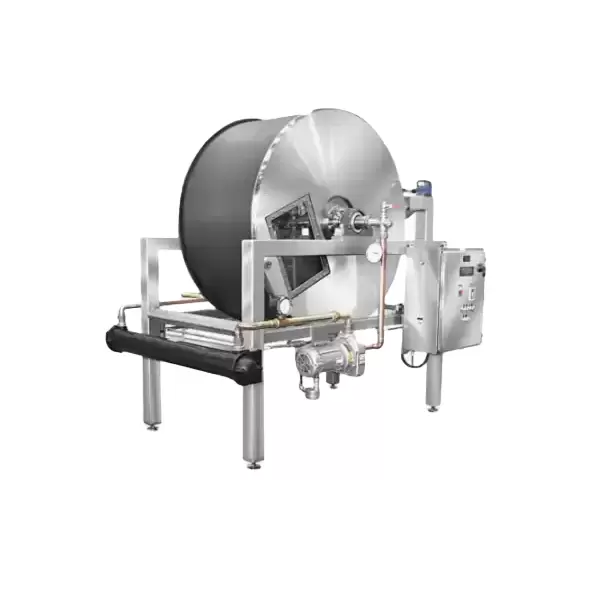

FEATURES of Latini-Hohberger Cooling Wheels

- Stainless Steel precision machined and polished drum surface.

- FDA approved durable hard-baked non-stick drum surface treatment available for sticky or high cooked caramel. (Optional)

- Stainless Steel sanitary tubular mainframe.

- Completely enclosed gear drive with AC inventor speed control.

- Drum sides insulated and Stainless Steel shrouded for improved cooling

- No drum side condensate drip.

- Stainless Steel batch size or continuous feed product hoppers available with adjustable product thickness metering blades and Rollers.

- Closed loop water recirculation system with water to water heat exchanger provided.

- Special machine construction available for continuous or batch process.

- Occupies minimal floor area.

- Special construction drum sizes available up to 10 feet in diameter.

| SPECIFICATIONS / DESCRIPTIONS / ESPECIFICACIONES : | LCD - 4030 | LCD - 6030 | LCD - 6040 |

|---|---|---|---|

| Capacity (min / max) | 1200 lb / hr 182 / 545 kg / hr | 2200 lb / hr 455 / 1000 kg / hr | 3000 lb / hr 682 / 1360 kg / hr |

| Temperature reduction | 110°F to 043°C | 110°F to 043°C | 110°F to 043°C |