SELL MOREWITH GROWCYCLE

Join as a seller and connect with thousands of B2B buyers nationwide!

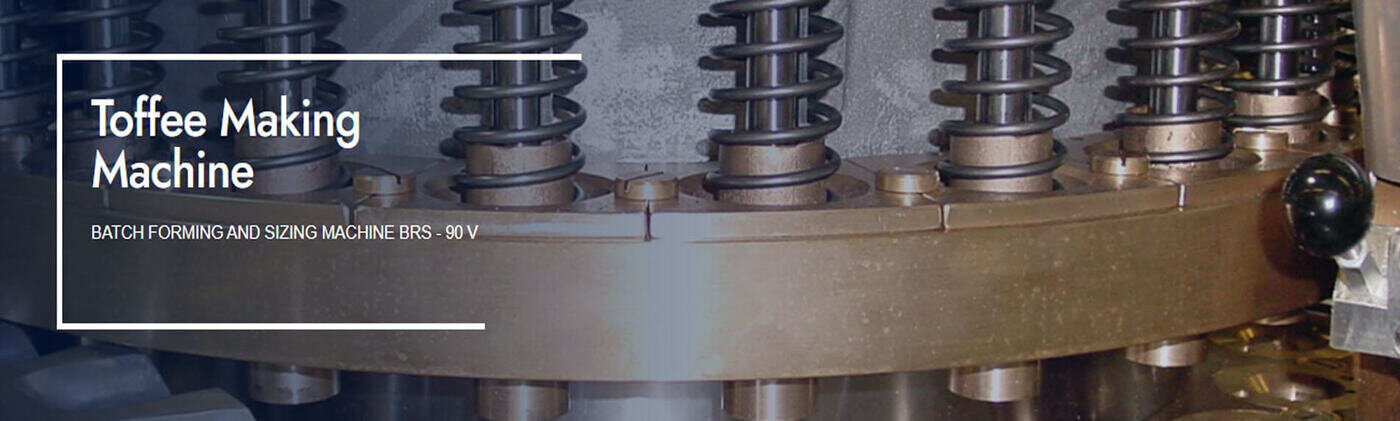

Latini’s Universal Batch Sizing Machine delivers a predetermined candy rope with the help of conical rollers. The conical-shaped rollers work with an alternate movement ensuring the mass of the candy, toffee, lollipop or other related products remains malleable enough to be processed further in the candy-making process. Latini’s Batch Sizing Machines or Batch Former has the feature of a motorized up-down and electronically forward reverse system that keeps the control in the operator’s will for better utilization and production. The rollers of our Candy Batch Sizing Machines can be removed without the need for any additional tools. Keeping in mind the good manufacturing practices for confectionery manufacturers, the Batch Sizing Machines ha been developed to assist a thorough and through-out cleaning of the machine, including the rollers. These stainless steel batch rollers are spring-loaded for automatic adjustment, saving you the hassle of frequent manual adjustments. The variable rate of speed is available to ensure uniformity of the finished product. In addition to that, Latini also offers left or right-hand-operated units as per your requirements.

One could easily say that a Batch Forming Machine is almost a necessity for every confectionery manufacturing facility. Without a dependable Batch Forming Machine, the forming and sizing process of your candy deters greatly which in turn also affects the shape and even the speed of candy forming. To ensure that you don’t end up with greater quantities of de-shaped or ill-weighted candies, it is imperative that a confectionery manufacturing facility invests in a complete Batch Forming Machine.

Latini offers you a variety of Confectionery Manufacturing Machines, complete from batching and dissolving of sugar and processing of syrup, to the cooking, cooling, pulling, rope sizing, forming, wrapping, and packing all from one source. What else would a person searching for Batch Forming Machines require more when they have found a one-stop solution by Latini-Hohberger Dhimantec?

Latini’s BRS-90 aids in the preparation of candy, toffee, and lollipop mass by forming and sizing it to the desired size and width. The confectionery mass is fed to the Uniplast Sweet Forming Machine and Batch Forming Machine available with the Rope Sizing Machine. The confectionery sector has benefited from Latini’s creative and tried-and-true solutions. Our 75-year experience sets us different and allows you to perfect your product. Whether you're a large organization or a newcomer to the sector, we'll help you choose the correct equipment, develop recipes, and train you on how to get the most out of your new candy machinery.

Three and Five Stage Rope Sizer

BRS - 90 Series Batch former with rope sizer combination is available with single to six sets of sizing wheels and optional 4 wheel cluster after the batch former.

No reviews found