SELL MOREWITH GROWCYCLE

Join as a seller and connect with thousands of B2B buyers nationwide!

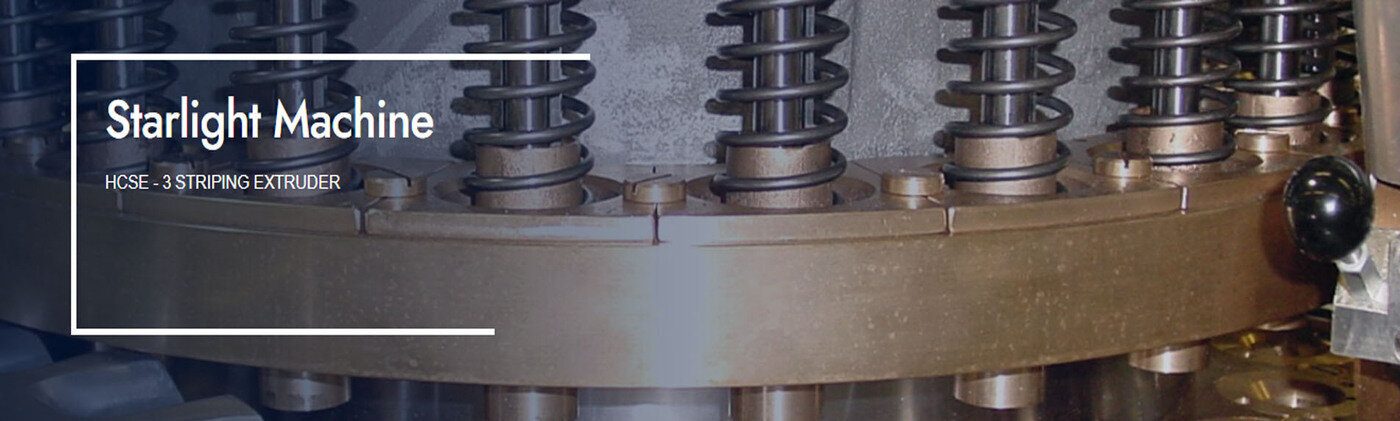

| SPECIFICATIONS / DESCRIPTIONS / ESPECIFICACIONES : | |||

|---|---|---|---|

| Capacity / Capacité / Capacidad | Up to 3000 Ib / hr 1360 kg / hr | ||

| Rope Diameter / Diamètre de la bande de bonbon / Diámetro de masa | 3"(75mm) | ||

| Dimension / Dimension / Dimensión | |||

| Length / Longueur / Longitud Width / Largeur / Ancho Height / Hauteur / Altura | 110 "(2800mm) 45"(1150mm) 68"(1730mm) | ||

L'extracteur de bonbon sous forme de bande permet d'automatiser le procédé difficile consistant à constituer deslots de bonbon en bande. L'extracteur de bonbon en bande utilise de l'huile chaude afin de maintenir une bonnetempérature de la masse de bonbon et de sa viscosité. Le bonbon en bande peut alors être passé dans la machinede confection Starlight, ou, il peut servir en tant que bonbon en bande dure pour fabriquer d'autres produitspopulaires tels que les sucres d'orge et les bâtons.

Este extrusor automatiza el difícil proceso de conformar una tanda marcada. El extrusor con camisa de aceitecaliente mantiene apropiadas temperatura y viscosidad de la masa para caramelos. La masa de caramelosmarcada resultante puede enviarse a nuestra máquina formadora Starlight, o puede suministrar caramelo marcadopara otros productos tales como bastoncitos y palitos.