Description

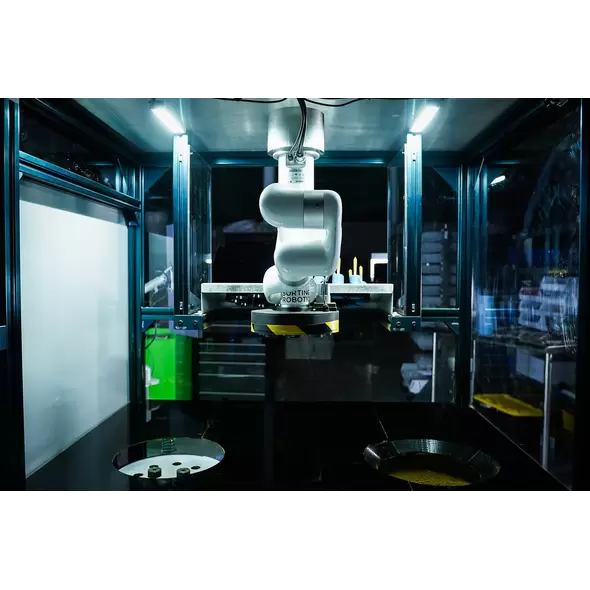

The Stardust by Sorting Robotics is a revolutionary machine designed for precision and efficiency in the dusting and adhesive application process for various rolled products. It is engineered to cater to high-output needs while maintaining top-notch quality, making it a valuable tool for businesses involved in mass production. This machine is highly versatile, adaptable to a variety of materials, and ensures consistency across all batches. Below is a detailed overview of its features, specifications, and operating requirements.

Unmatched Throughput and Versatility

The Stardust is built for productivity and ease of operation, ensuring that even high-demand environments are catered to seamlessly.

- Impressive Throughput: The machine can handle up to 1,200 rolled units per hour, delivering a rapid production pace while ensuring uniform results across all units.

- Single Operator Requirement: Designed with simplicity in mind, the Stardust requires only one operator, minimizing labor costs and operational complexity.

- Adaptability Across Sizes: Whether it’s cones, straight tubes, or blunts, the Stardust can handle rolled products of all sizes and types, offering unmatched flexibility.

Advanced Adhesive Application

The Stardust employs state-of-the-art adhesive application mechanisms, ensuring perfect results every time.

- Diverse Adhesive Compatibility: Works seamlessly with a variety of adhesive materials, including fully decarbed concentrates, distillates, cigar glue, and water-based formulations.

- Precision Dispensing: The adhesive reservoir ensures accurate and consistent application, reducing waste and ensuring uniform coating.

Efficient Dusting Mechanism

This machine takes dusting processes to a new level of sophistication, enabling efficient and consistent dust coating.

- Wide Material Compatibility: Suitable for use with dry sift powders, crushed crystals, and other powderized materials.

- Optimized Dust Bowl Design: Ensures even application and minimal material wastage during the dusting process.

Compact Design with High Performance

Despite its advanced capabilities, the Stardust is designed with a space-saving form factor, making it ideal for a variety of operational environments.

- Dimensions: Measuring 0.87 x 1.58 x 1.85 meters (2.8 x 5.2 x 6.1 feet), it fits easily into most production setups.

- Lightweight Yet Durable: Weighing 400 lbs (180 kg), the Stardust combines durability with portability.

- Quiet Operation: Operating at just 70 dB, it minimizes noise pollution, promoting a comfortable working environment.

Operational Requirements

To achieve optimal performance, the Stardust has specific operational requirements.

- Power Needs: Requires 20A @ 220VAC power supply for smooth operation.

- Air Supply: Needs food-grade dry, filtered air at 20 CFM @ 90 PSI.

- Temperature Range: Operates efficiently within an ambient temperature range of 50°F - 80°F (10°C - 27°C).

- Internet Connection: WiFi or Ethernet is essential for operation, allowing for easy updates and monitoring.

Components Overview

The Stardust includes all essential components needed for seamless operation.

- Kiefing Robot: The central unit that powers the entire process.

- Collet Pods (40x): Precision-engineered components for secure handling of rolled products.

- Dust Bowl (1x): Ensures uniform and efficient dusting application.

- HEPA Filters (4x): Maintain air purity and ensure clean operations.

- Adhesive Reservoir (1x): Facilitates accurate adhesive application.

Final Words

The Stardust by Sorting Robotics is a game-changer in the world of adhesive and dusting automation. Designed with efficiency, precision, and adaptability in mind, it caters to the needs of modern production lines. Whether your business focuses on mass production or small-scale operations, the Stardust guarantees a consistent, high-quality output with minimal effort. For businesses looking to optimize their production process, this machine is an investment in both time and quality.

Reviews

No reviews found